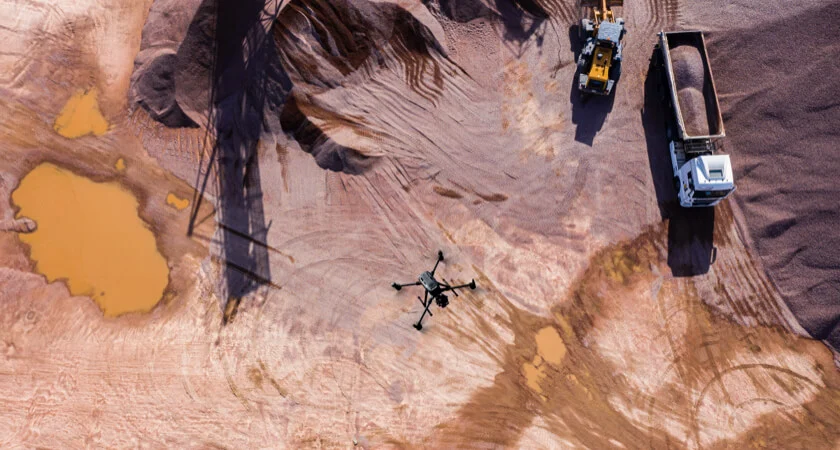

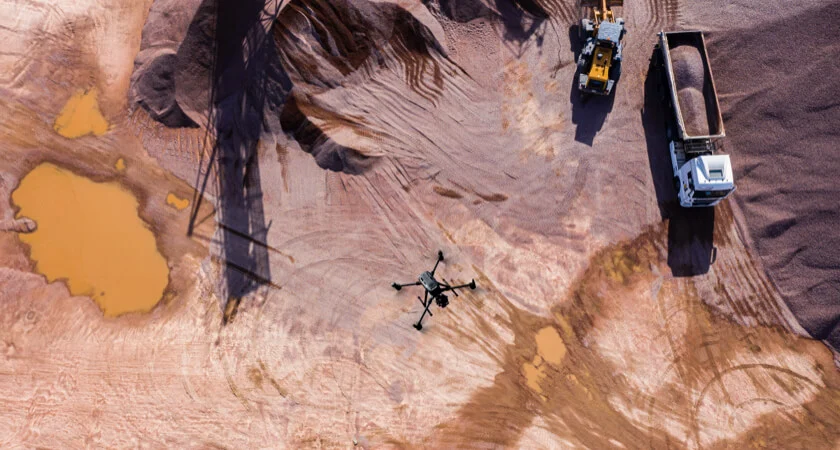

DJI Enterprise M300 M350 Payload for Mining

ZENMUSE H20 H20T – Equipment temperature detection via Thermal Camera.

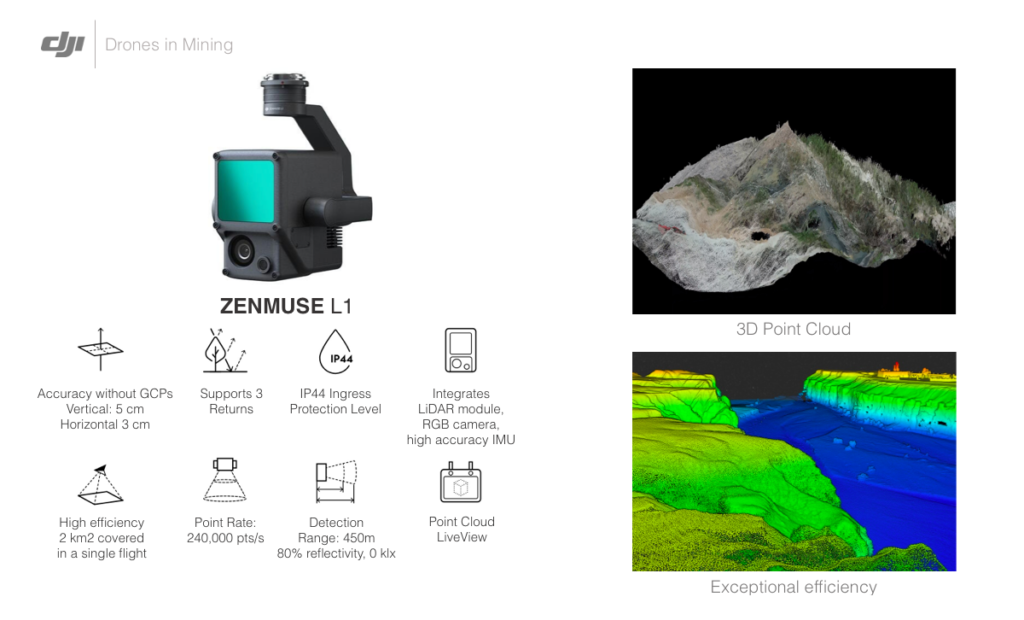

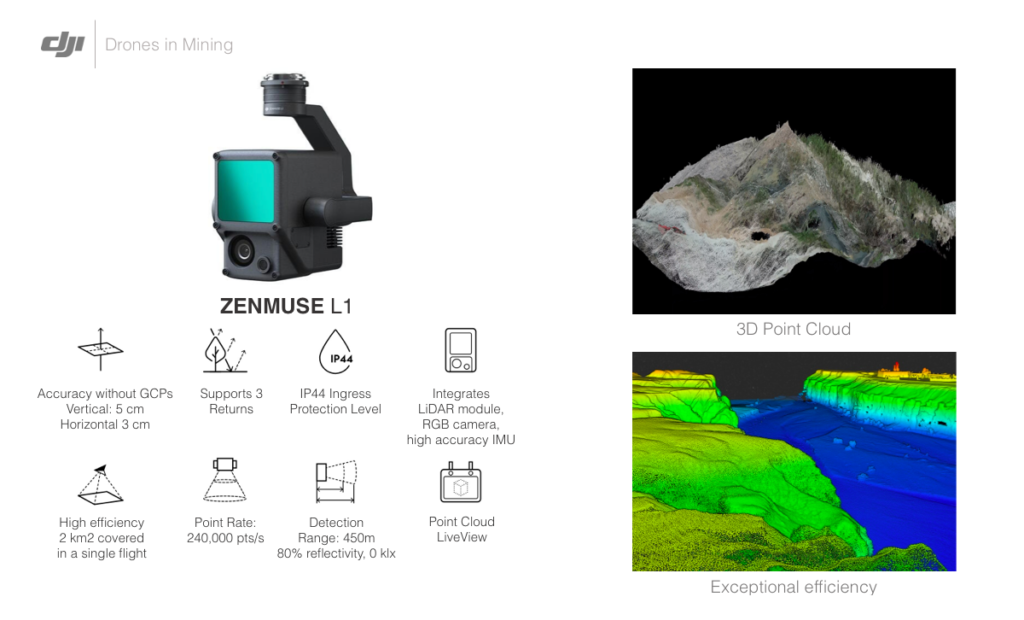

ZENMUSE L1 – 3D Point Cloud

DJI ZENMUSE P1 – For aerial surveying and photogrammetry

Electrical, Instrumentation, Industrial Distribution

DJI Enterprise M300 M350 Payload for Mining

ZENMUSE H20 H20T – Equipment temperature detection via Thermal Camera.

ZENMUSE L1 – 3D Point Cloud

DJI ZENMUSE P1 – For aerial surveying and photogrammetry

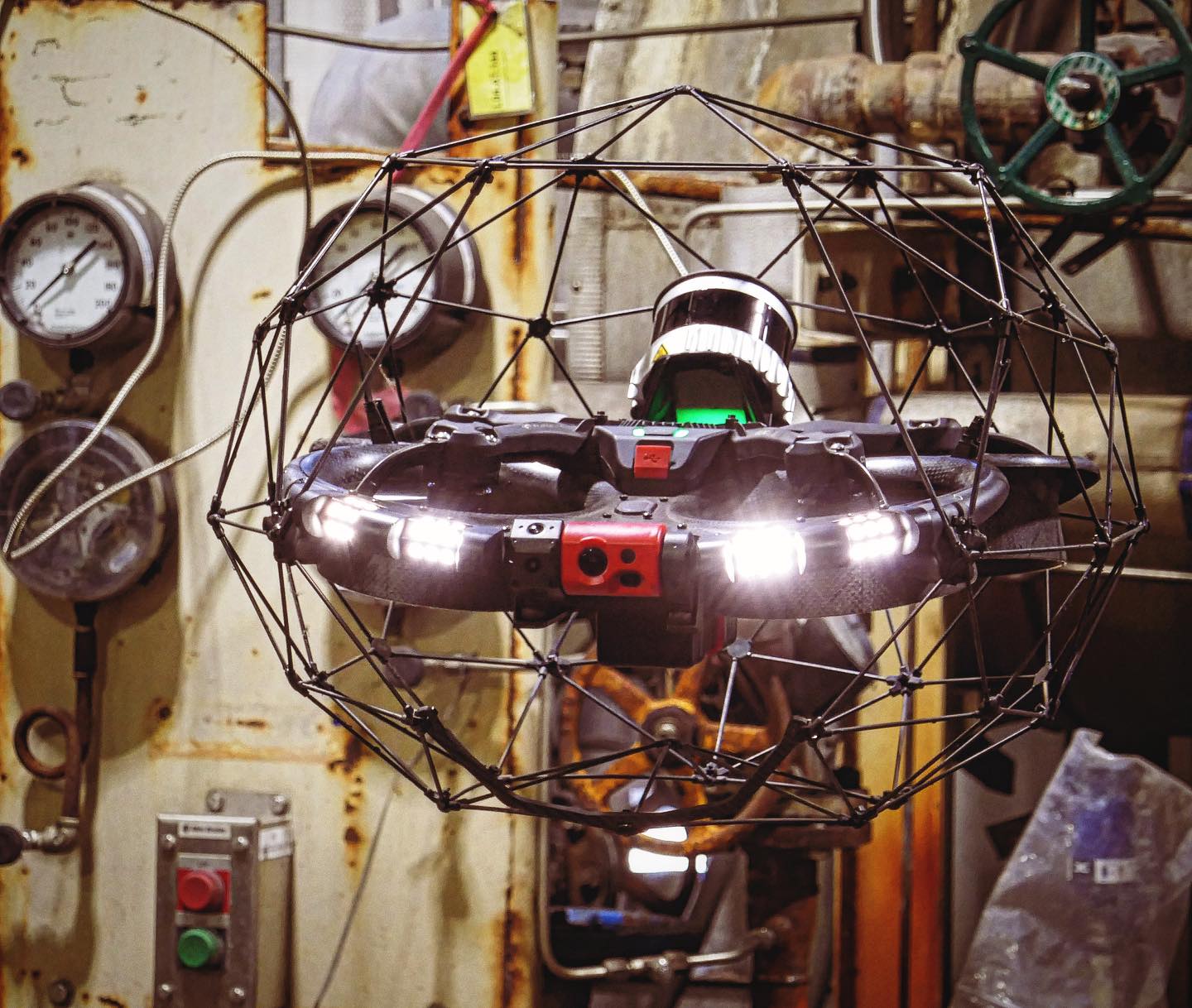

Increase savings for your internal inspections? Use Elios Drones.

How can you increase savings for your internal inspections?

By using ELIOS indoor drone to reduce downtimes, eliminate the need for scaffolding, and reduce the amount of labor required.

Let’s make these savings concrete.

These savings are not unique to a specific industry or type of inspection. Across industries, you can realize significant savings by using an indoor drone to reduce downtimes and eliminate the need for scaffolding in your internal inspections.

Improve Safety Using Industrial Inspection Drones

How can you improve safety for your internal inspections?

By using an indoor drone to eliminate or significantly reduce the need for inspectors to enter confined spaces to collect visual data.

It’s worth noting that these confined space and scaffolding statistics are just for the U.S. If you apply these numbers globally, it’s likely that there are thousands of deaths and tens of thousands of injuries every year associated with the work inspectors do in confined spaces. Death and injuries that could have been prevented using Elios inspection drone. Instead of entering confined and hazardous spaces themselves, inspectors can use an indoor drone to collect visual data, allowing them to remain safely outside.

Improve Safety Using Industrial Inspection Drones, contact us to learn more.

Reduced Downtimes Using Elios 3 Drones

How can you reduce downtimes for your internal inspections?

By using an indoor drone to eliminate the need for scaffolding and to speed up your data collection.

Scaffolding can take several days to put up and take down, adding dozens of hours of downtime to the internal inspection process. Indoor drones eliminate the need for scaolding by taking the place of inspectors in collecting visual data.

Speeding up data collection can have a big impact on reducing the total turnaround time needed for an internal inspection. Indoor drones can get full coverage of an area much more quickly than an inspector can by walking or climbing in the same area, all while retaining a high standard of data quality.

Preparation for confined space entry can be time-consuming, requiring work permits, the presence of rescue teams on site, and other preparatory work that using an indoor drone can help avoid.

Indoor drones have the potential to reduce the total amount of time needed for an internal inspection by 90% — or more.

3D level scanners—also known as 3D solids scanners—provide continuous, non-contact level measurement using dust-penetrating technology for unsurpassed bin volume accuracy. Unlike single point devices, 3D scanning performs surface topography measurement and accounts for irregular surfaces when performing volume calculation. The sensor, previously referred to as a 5708, can detect cone up and cone down conditions or sidewall buildup. Bulk acoustic wave technology is proven to perform in powders and bulk solids contained in bins, tanks, silos, domes, warehouses, covered storage bunkers, and piles.

DJI Enterprise Solutions For Electric Utilities

Inspections:

Digitalization

Other Uses Cases

Please contact us to request for detailed presentation of how DJI Enterprise Drones can help Electric Utilities operations.

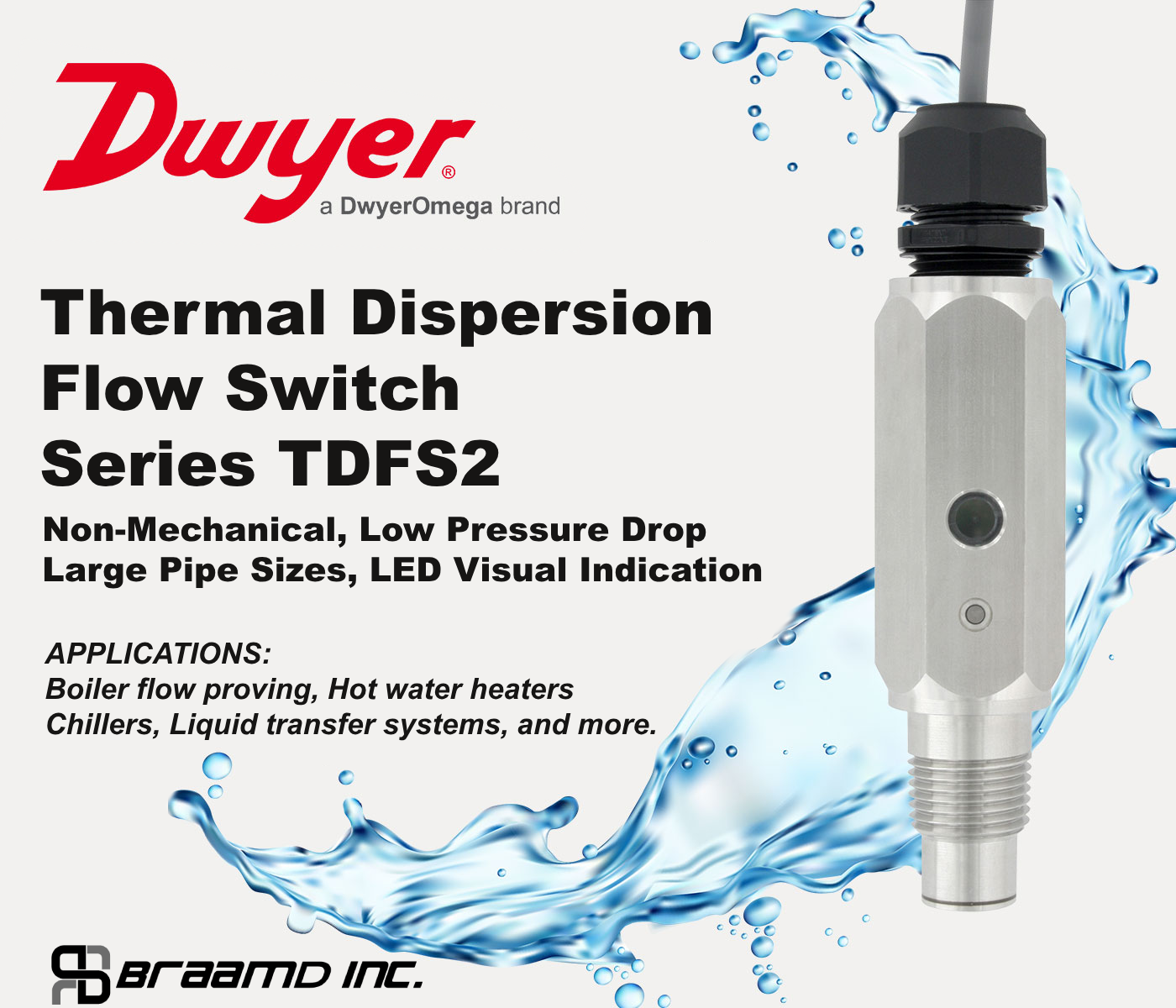

The Thermal Dispersion Flow Switch, Series TDFS2, is ideal for applications such as: liquid transfer systems, boiler flow proving, hot water heaters, and chillers. The TDFS2 provides long term reliability and life expectancy compared to mechanical flow switches as there are no moving parts to maintenance. This switch only needs to be installed 10 to 25% into the process, minimizing pressure drop. In addition, the 316 stainless steel construction is NEMA 4X rated for a wide variety of applications.

Please click below to RFQ:

PHOENIX Non-contact Radar Sensor for Irrigation Channel & Water Supply & Power Plant

Task definition

Solution

BRAAMD Inc. is an authorized and trained distributor of FLOW-TRONIC Flow Solutions in the Philippines. Contact us for more information, request for quotation, or actual demo of Raven-eye and Phoenix Sensors.

Email: [email protected], [email protected], [email protected]

*Photo: For reference only.

If you have ever heard the term “drone program” and have wondered what it is, let one of our biggest customers tell you more about it. Holcim and their Plants of Tomorrow program are one of Flyability’s historical partners and we have been working together towards one goal: making the cement industry safer and more efficient! Holcim has been a promoter of our technology in the cement industry for years because of Elios’s unrivalled quality and performance. At Flyability we are working hard to make Elios 3 the best tool for inspectors in the cement industry. Our mission? No more humans doing dangerous jobs!