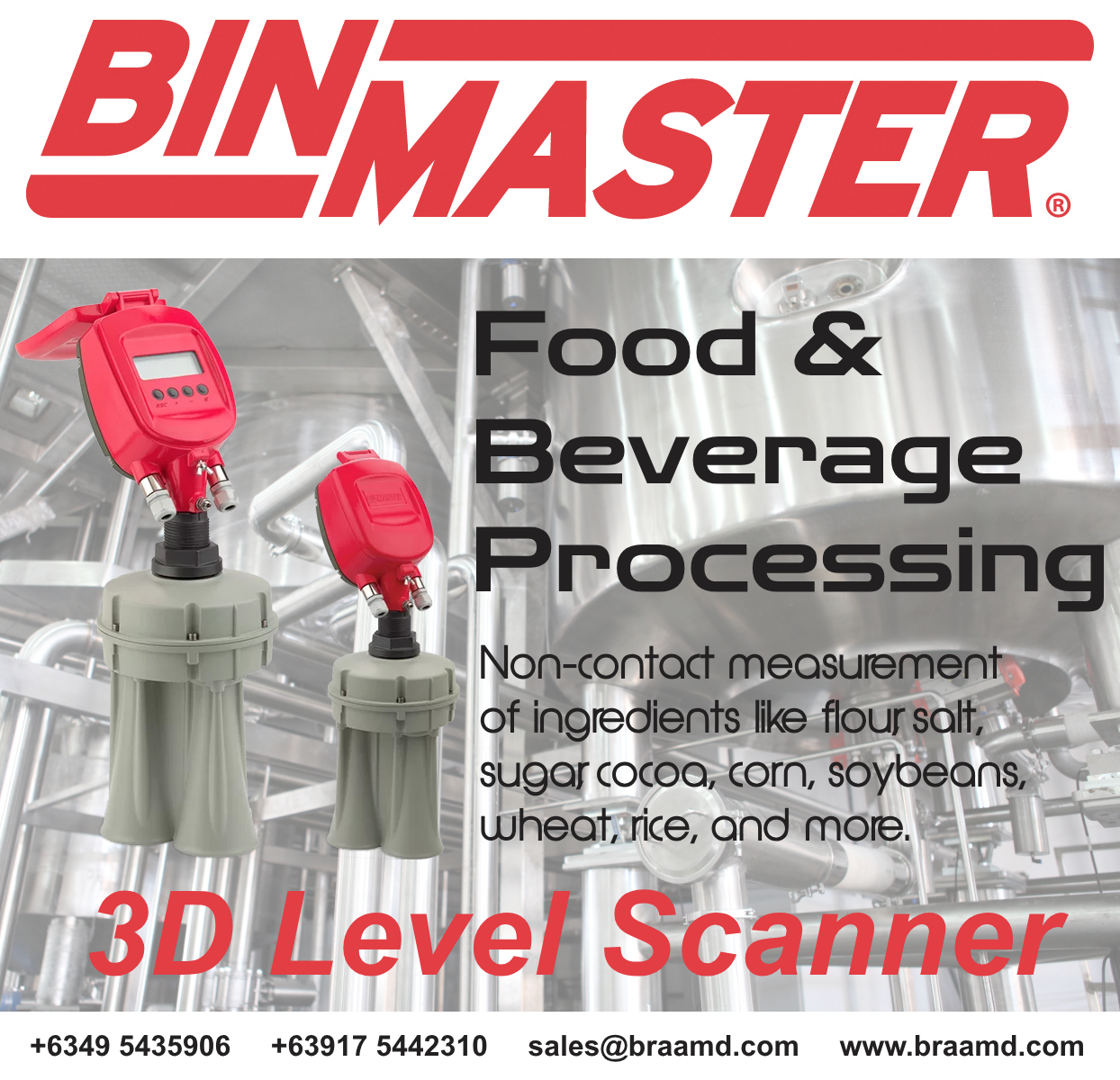

BinMaster Sensors for Food Processors

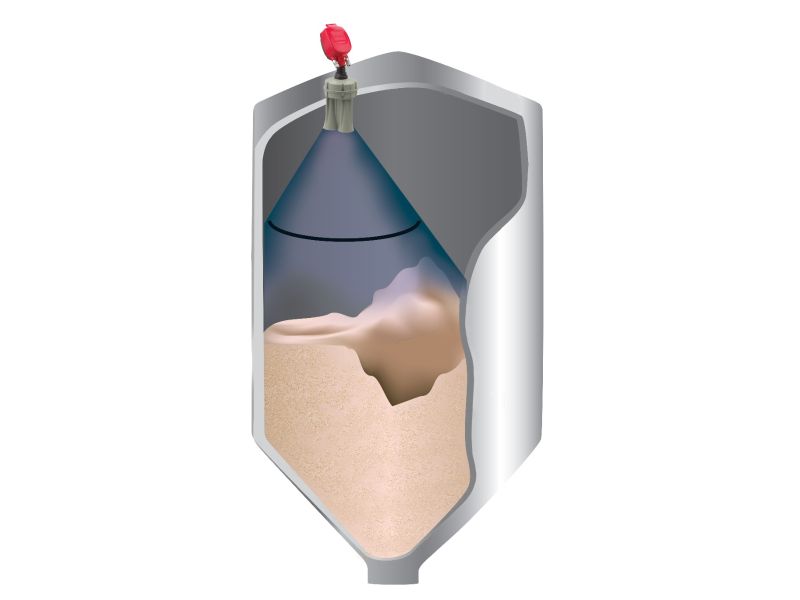

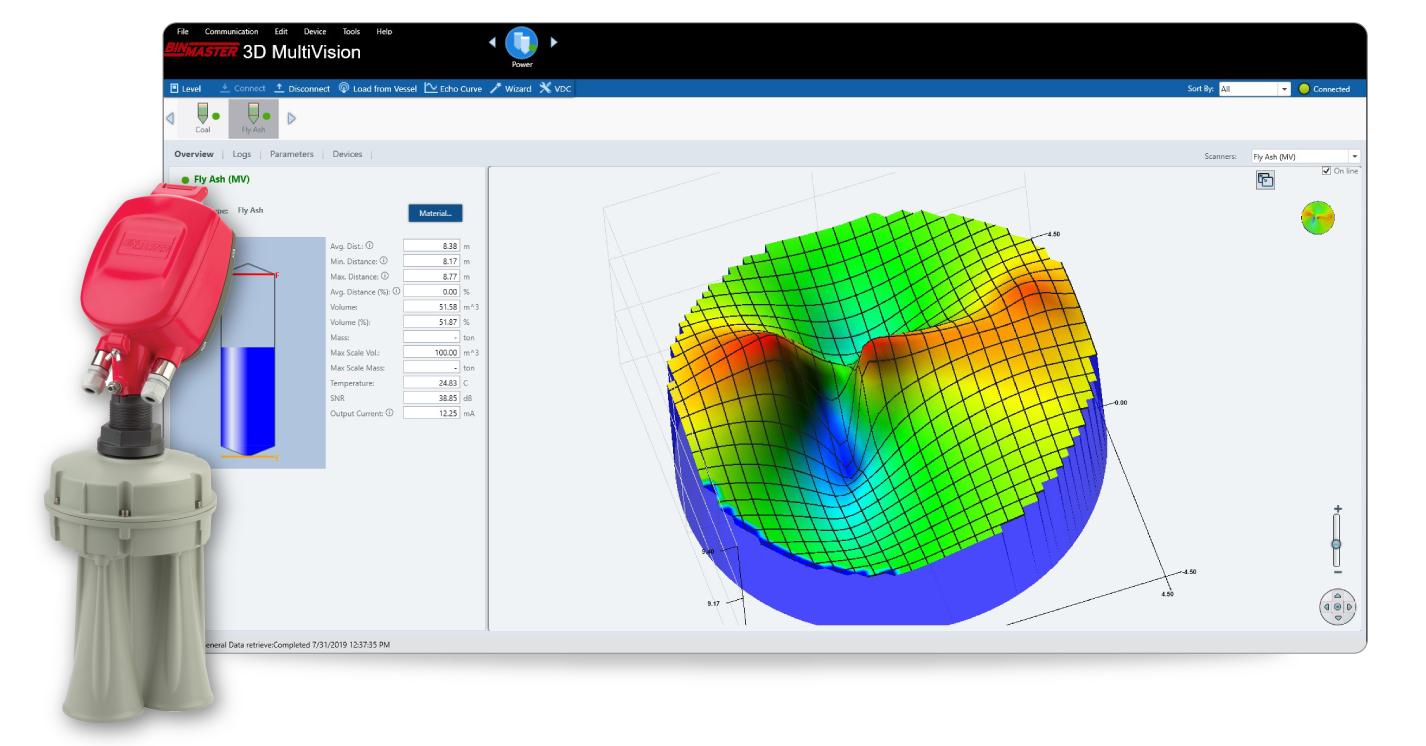

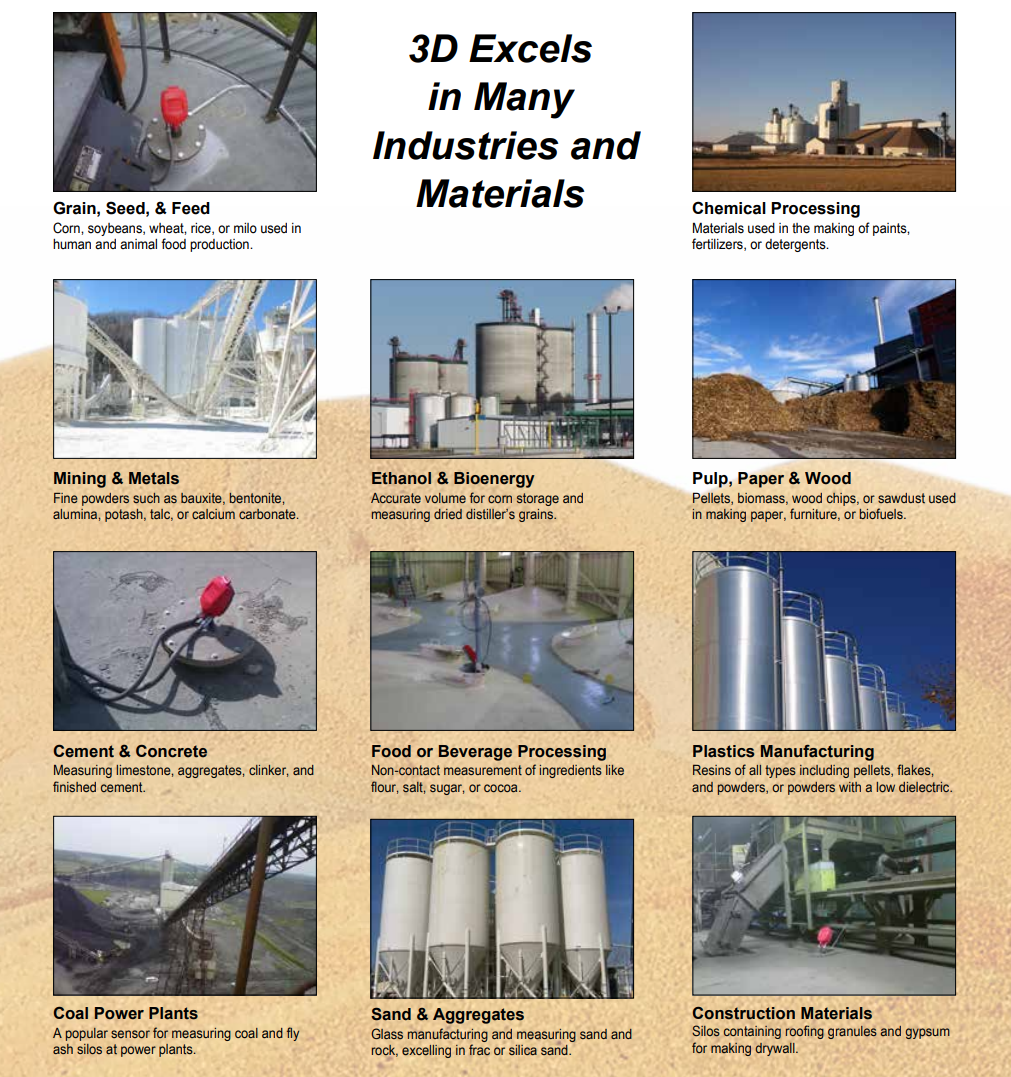

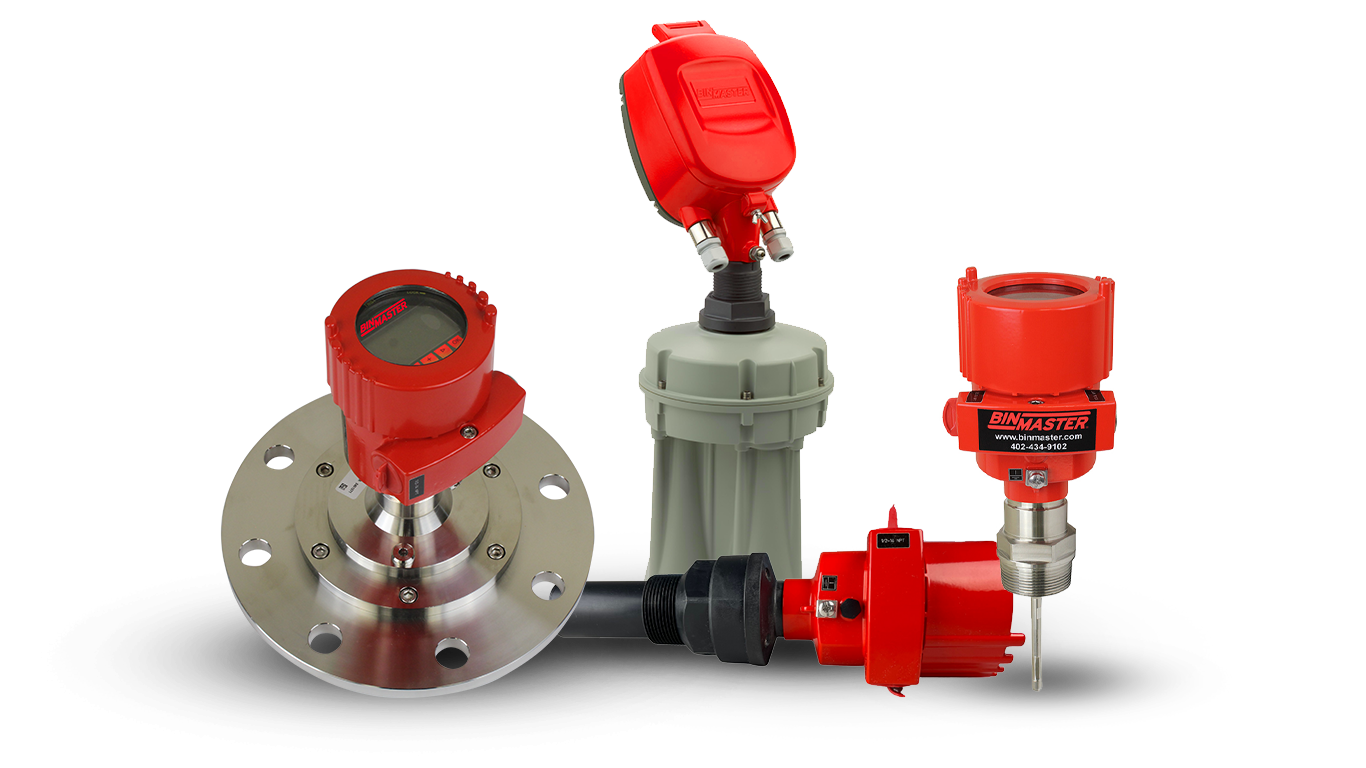

Food processors need to measure ingredient levels in storage and process silos, mixers, and batching tanks, or on conveyors and in pipelines. To ensure food quality, level sensors must comply with FSMA food safety and meet hygienic, CIP or clean-in-place requirements to reduce the risk of contamination and prevent out-of-spec batches. From brewing to baby food, and solids to slurries BinMaster has the solutions for inventory monitoring.

We will help you address these challenges:

- Powders, solids, liquids, and slurries that all behave differently

- Process downtime caused by shortages of key ingredients

- Not enough system capacity causing processing delays

- Loss of inventory control that leads to spoilage

Please discuss your process or material handling problems with our Sales & Application Engineers. Email us at sales@braamd.com