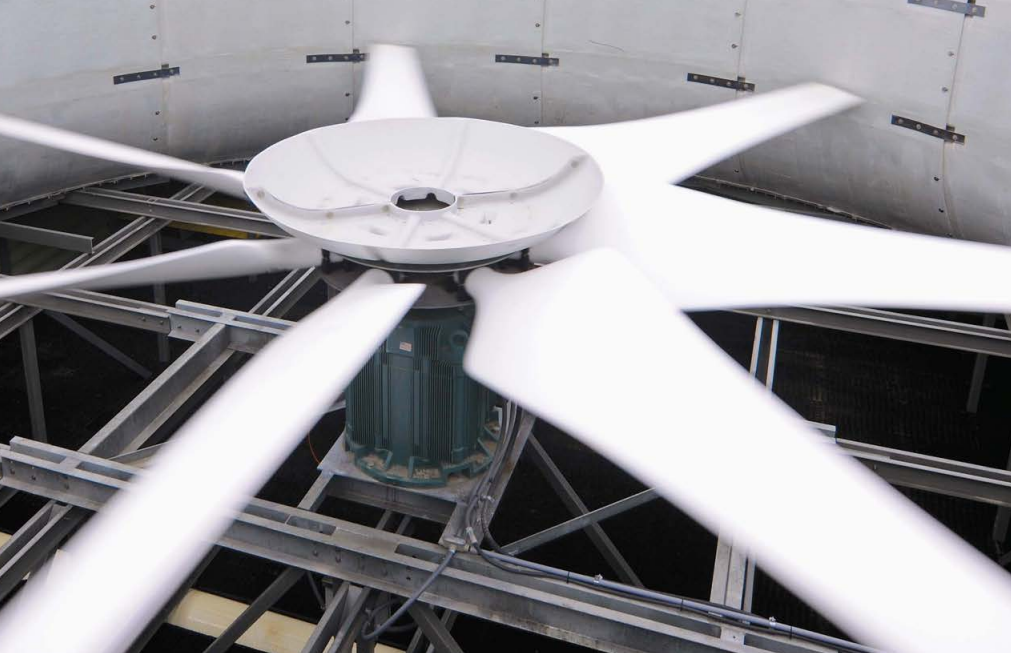

Industrial cooling direct drive ABB Baldor-Reliance motor (and VSD)

Simplicity. Reliability. Energy savings. Everything counts.

ABB’s Baldor-Reliance RPM AC Cooling Tower direct drive motor and variable speed drive packages for industrial cooling replace the gearbox, driveshaft and induction motor typically used in cooling towers. This combination provides high torque and low speed required for these applications without additional drivetrain components. This results in less parts, less maintenance, lower noise and reduced risks.

Direct drive motor and VSD packages can be used either in wet or dry cooling towers, air cooled condensers (ACC) of air cooled heat exchangers (ACHE). Whether you are from power generation, district energy, metals or food and beverage industry, our direct drive motor and drive packages are the perfect solution for your needs in industrial cooling.

Direct drive cooling tower motor and drive benefits:

- Less parts, less maintenance, reduced risks

- Reduce maintenance and improve reliability. With this package, you can remove the gearbox, gearbox cooling system, driveshaft, couplings and bearings. This means no more gearbox maintenance, no gearbox oil leaks, no cooling water contamination and no long lead times for replacement parts.

- Same technology can be also offered in conventional, yet power dense, foot mounted designs that replaces the belt and sheave applications

- Lowers vibration and system noise

- Saves energy and eliminates startup current peaks and stresses from across-the-line startup. The drive smoothly accelerates and decelerates the fan to the speed needed, rather than running directly on line.

- Anti-windmilling technology controls fan blades when the system is not operating

- Simplified fan drivetrain alignment, only need to align the fan to the motor shaft, supported by a global service network that ensures local support, no matter where the motor and drive are installed.