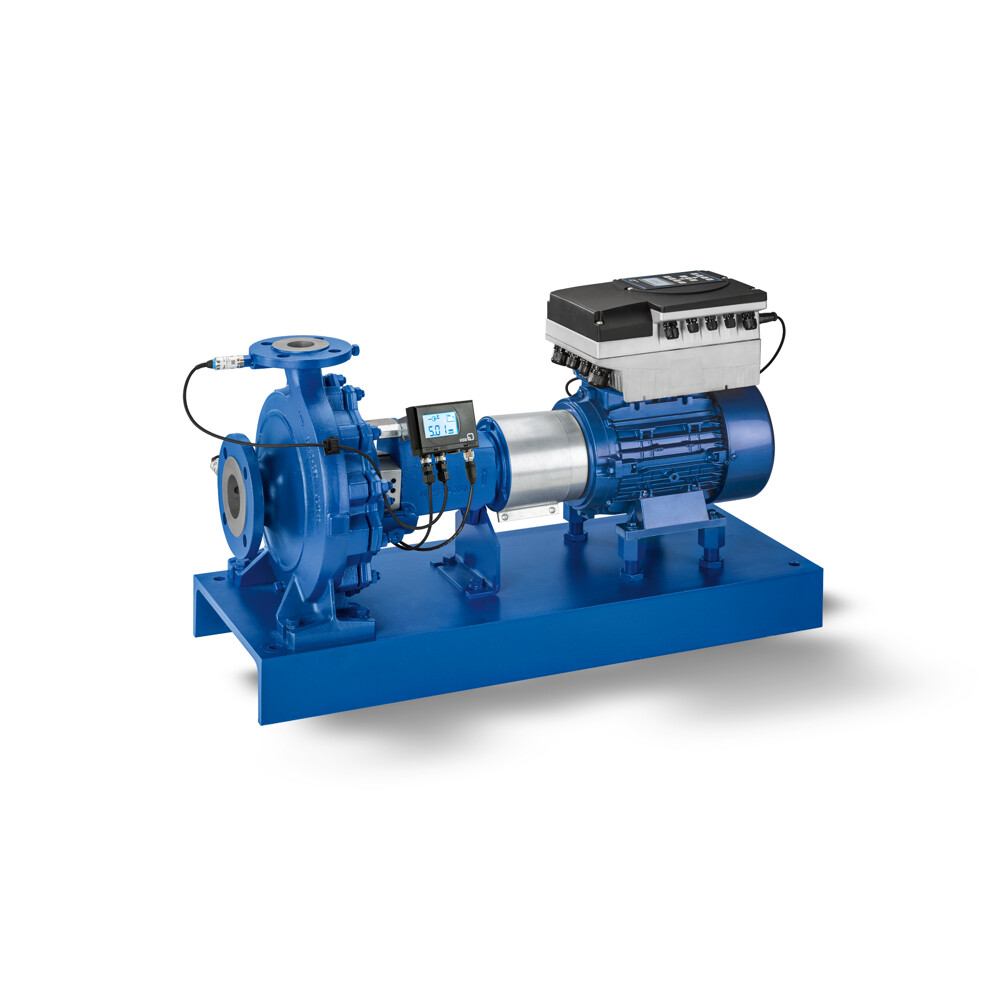

Description

Horizontal volute casing pump, single-stage, with ratings and main dimensions to EN 733, long-coupled, back pull-out design, with replaceable shaft sleeves / shaft protecting sleeves and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

Features:

Excellent energy efficiency

- Advanced hydraulic system with high efficiencies: As standard, the impeller diameter is trimmed to match the duty point.

- Intelligent pump monitoring with KSB’s PumpMeter (optional)

- Intelligent variable speed system with KSB’s PumpDrive and KSB SuPremE® motor: energy savings of up to 60 percent

- ErP Directive (MEI ≥ 0.4): Minimum requirements are exceeded by far.

Reliable operation

- Pump hydraulic system with low NPSH values and optimum suction characteristics

- Confined volute casing gasket

- Large stud diameters and threads (M12/M16)

- The shaft protecting sleeve prevents wear of the pump shaft.

- The conical seal chamber of the mechanical seal prevents internal circulation and improves venting and flushing.

Wide range of variants

- Large range of shaft seals: single mechanical seal, gland packing and double mechanical seal as standard

- Large variety of materials for the most diverse of fluids handled

- Large number of pump sizes: 62 for Etanorm

- Flanges to EN 1092, optionally with ASME bolt hole pattern (Etanorm only)

Ease of service

- Easily replaceable casing wear rings reduce wear at impeller and casing cover.

- Forcing screws at casing cover facilitate dismantling of the pump casing.

- Available as an option: KSB Guard for monitoring temperature and vibrations

Applications:

- Handling clean or aggressive fluids not chemically and mechanically aggressive to the pump materials.

- Water supply systems

- Cooling circuits

- Swimming pools

- Fire-fighting systems

- General irrigation systems

- Drainage systems

- Heating systems

- Air-conditioning systems

- Spray irrigation systems

Technical Data

- Function –Pump

- Connection type –Flange

- Drive concept – With electric actuator, Combustion engine

- Max. flow rate – 1368 m³/h

- Min. flow rate – 1.5 m³/h

- Max. head – 160 m

- Min. head – 2 m

- Mains frequency – 50 Hz, 60 Hz

- Mains voltage – 400 V, 460 V, 220 V, 230 V, 240 V, 380 V, 415 V, 500 V, 575 V, 660 V, 690 V

- Casing material – EN-GJL-250/A48 CL 35B, CUSN10-C-GS/B30 C90700, GX5CRNIMO19-11-2/A743 GRADE CF-8M, EN-GJS-400-15/A536 GRADE 60-40-18

- Nominal pressure – PN 16, PN 10, CL 150, CL 125

- Max. allowed working pressure – 16 bar

- Suction behaviour – Non-self-priming

- Max. allowed fluid temperature – 140 °C

- Min. allowed fluid temperature – -30 °C