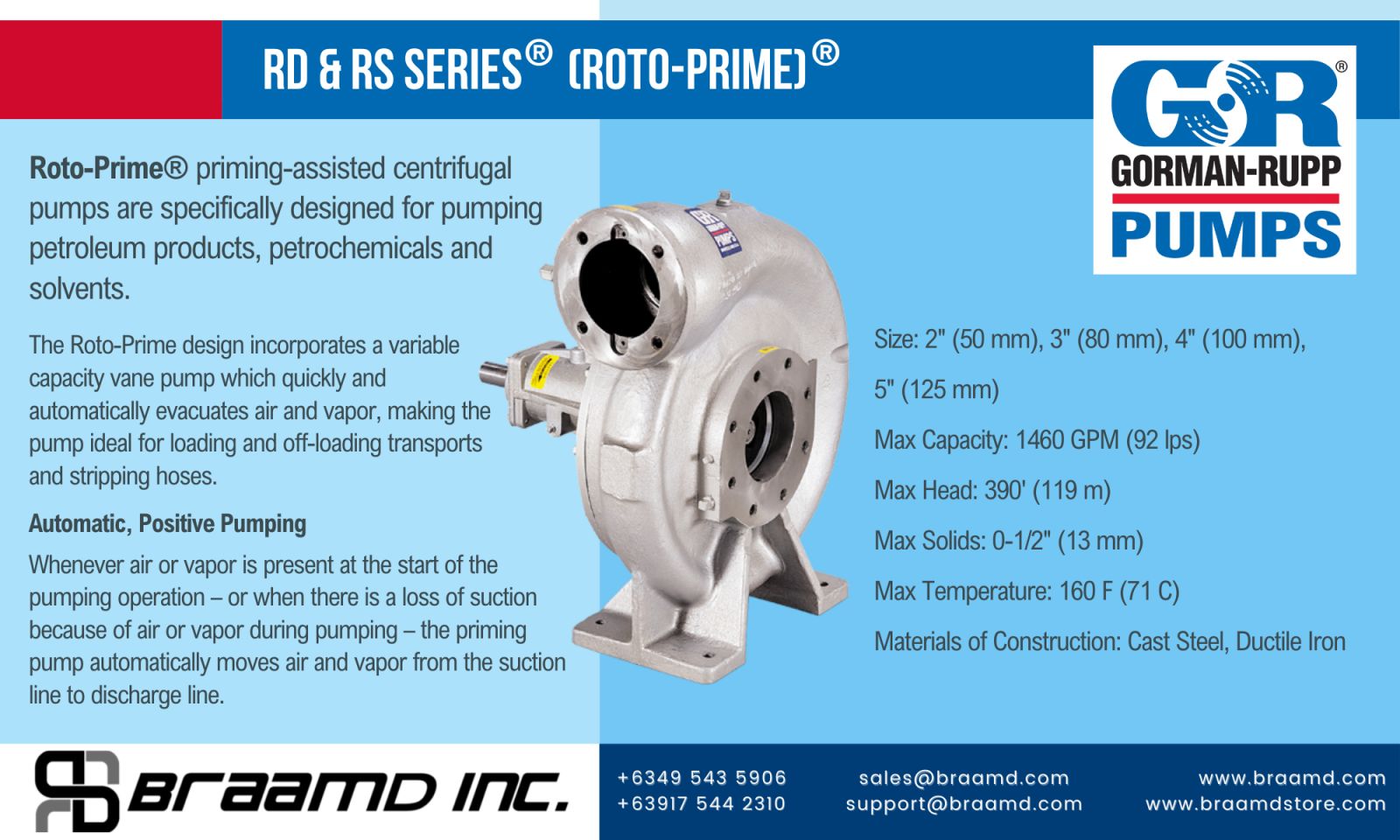

Gorman Rupp ROTO-PRIME® Priming-Assisted Petroleum Pumps

Roto-Prime® pumps are actually two pumps in one: a variable capacity vane pump used during the priming cycle,

and a standard centrifugal pump to move the liquid.

Whenever air or vapor is present at the start of the pumping operation – or when there is a loss of suction because

of air or vapor during pumping – the priming pump automatically moves air and vapor from the suction line to

discharge line. Once the flowing liquid from the centrifugal portion of the pump builds up sufficient pressure in the

discharge system, the pressure backs up through a tube to act on the bottom of the priming pump’s movable slide

block, placing it in a neutral position during normal operation.

Full Priming.

With air or vapor in the lines, pressure of the spring on top of the movable slide holds the priming pump in full pumping position.

Neutral

When air and vapor are removed, liquid pressure equalizes spring pressure and the pump automatically slides into neutral… where it remains until air and vapor again appear in the system.

Partial Priming

As the pump evacuates air and vapor from the lines, liquid pressure builds up on the underside of this slide, moving

it upward toward neutral.

Please click here to check complete information and specifications.