Binmaster for Cement Industry, Inventory Monitoring.

Cement plants rely on high productivity and efficiency to reduce costs and increase profit margins. Batch control is critical to quality control and waste reduction. BinMaster’s heavy duty level sensors excel in dust and stand up to sand, grit, gravel, clinker, and rock. Plants can optimize operations with a complete solution for real-time inventory monitoring. Binmaster products for cement plant inventory monitoring:

3DLS S, M OR MV 3DLevelScanner – 3DLevelScanner uses advanced acoustics-based technolgy and multiple point measurement to provide precise inventory management.

MVL 3D Multiple-Scanner System – This multiple-scanner system integrates two or more 3DLevelScanners to accurately measure inventory in very large or wide diameter bins, tanks, or silos.

3DLS HT 3DLevelScanner for High Temperatures – 3DLevelScanner specifically designed for for use in challenging materials such as clinker, alumina, frac sand, and fly ash. This model operates at temperatures up to 356°F (180°C).

RL Acoustic Level Sensor – Non-contact level sensor that provides provides continuous level measurement for all types of powders and solid materials.

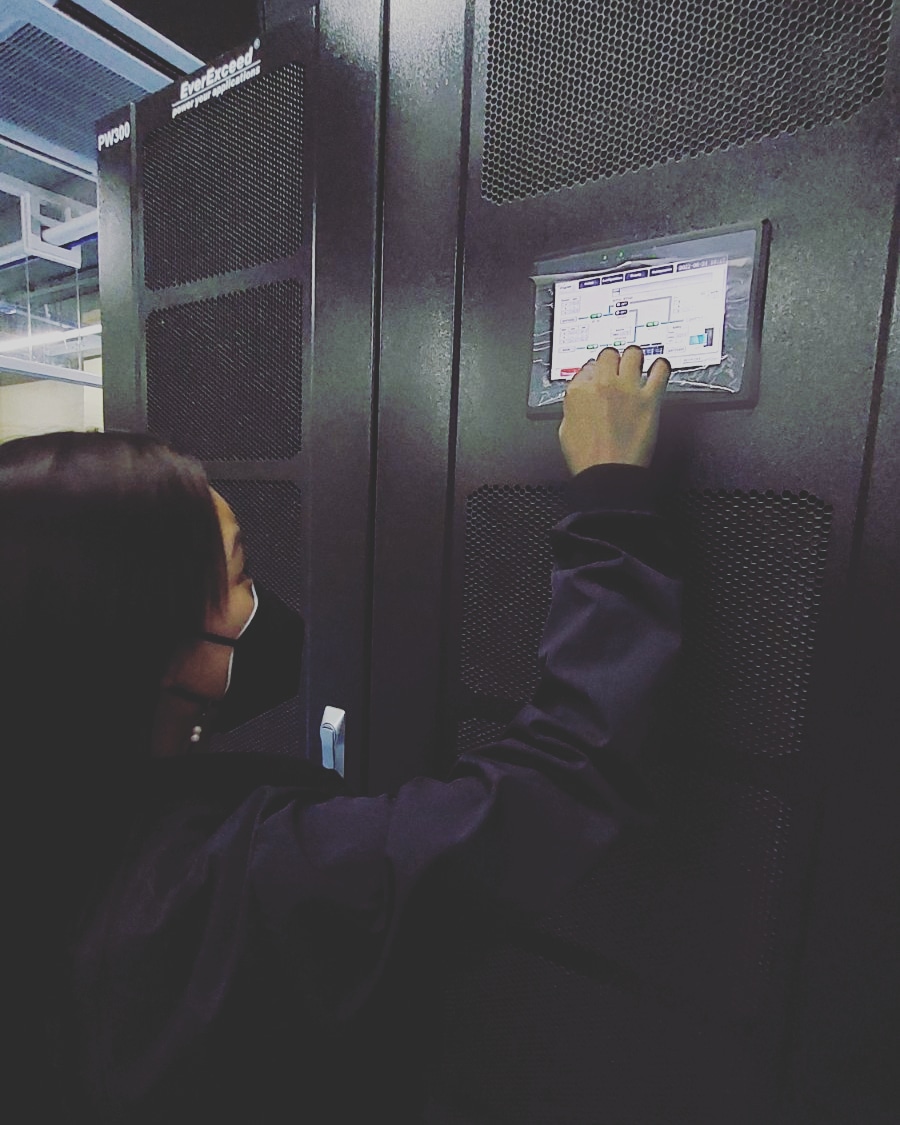

3D MultiVision Software – Inventory management software provides 3DLevelScanner users an easy and convenient way to monitor data from multiple bins.

We have a number of Binmaster installations in cement plants (and power plants as well) in the Philippines. We hope to set up a meeting and we’ll show the principle of operation and actual installations.