BRAAMDrones – DJI Cap Giveaway

May DJI cap ka na ba?

Pag wala pa, follow BRAAMDrones.

Malapit na tayong mag-draw ng winners sa BRAAMDrones.

Electrical, Instrumentation, Industrial Distribution

BRAAMDrones – DJI Cap Giveaway

May DJI cap ka na ba?

Pag wala pa, follow BRAAMDrones.

Malapit na tayong mag-draw ng winners sa BRAAMDrones.

Festo’s pinch valve, VZQA, is packed with features.

Light, compact and easy to clean is always one of the considerations in designing a system

Festo’s pinch valve, VZQA, is packed with features. The normally closed configuration is also the smallest in dimension you can find in the market.

Get in touch with us with your most difficult medium; abrasive powder, viscous jelly, vacuum.

Reduce compressed air consumption and CO2 emissions with Festo Energy Saving Services (FESS)

Energy efficiency experts from Festo analyse your entire compressed air system from compressed air generation to pneumatic applications. This holistic approach gives you a comprehensive overview of all energy-saving potentials. The service offering consists of 6 modules which are certified by TÜV Süd in accordance with ISO 11011.

BRAAMD is now an Authorized Festo Energy Savings Service (FESS) Partner.

Festo Solutions for the biotechnology, pharmaceutical and cosmetics industry

The production of pharmaceutical and cosmetic products demands cutting-edge technologies and a high level of #automation. That’s where Festo comes in, with their ingenious solutions tailored to enhance manufacturing processes in these fields.

From raw materials storage to API production, formulation to filling, packaging to palletizing, Festo’s solutions are here to streamline your entire value chain. Plus, they can be tailored to your specific needs.

Product highlights for the biotech, pharmaceutical and cosmetics industries:

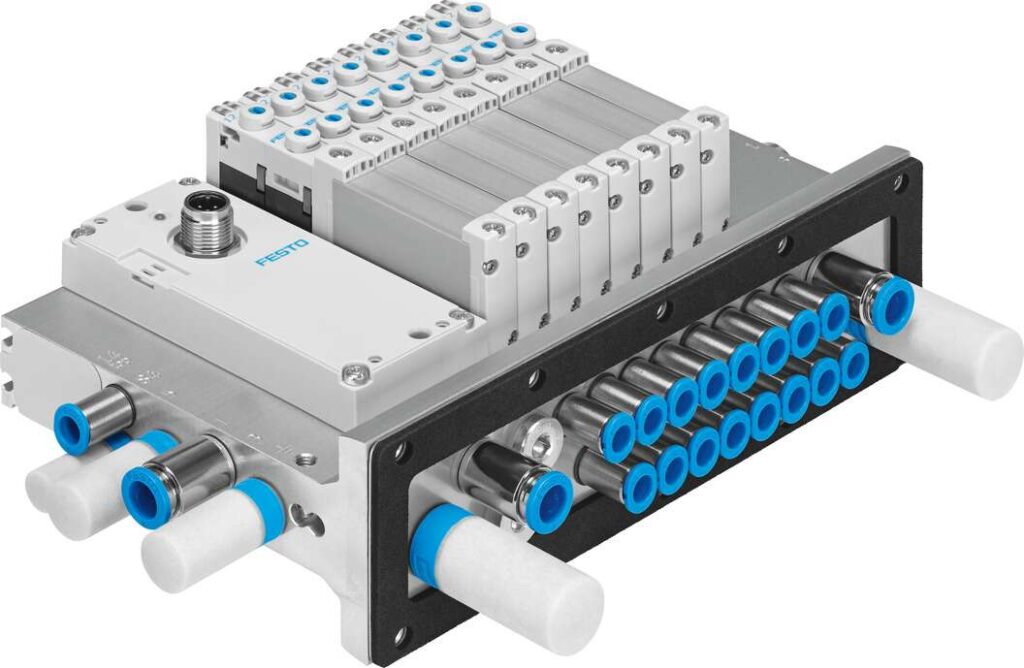

Valve terminal VTUG-EX with multi-pin or fieldbus interface

Optimised for space-saving control cabinet installation. Can be used in Ex zone 2/22 according to IECEX, CCC, UL-Hazloc Class /Divison 2.

Automation system CPX-AP-I

The new decentralised l/O system is great in combination with the valve terminal VTUG. Up to 80 participants can be connected to one bus node.

Festo Positioner CMSH

The new 2-conductor positioner CMSH for safe and reliable control of pneumatic actuators. Extensive diagnostic options, HART protocol and simple integration via EDD or FDT in host systems.

Click to find out more about automation solutions for Biotech, Pharma, and Cosmetics industries.

Integrated control cabinet solutions with CPX-E and VTUG

An ideal combination – compact and high-performing: the automation system CPX-E and the valve terminal VTUG together in a control cabinet. This is a complete solution for use in the process industry that keeps tubing installation to a minimum.

More information:

Why the Matrice 300 RTK Is an Inspector’s Dream Tool

New Smart AI capabilities make drone inspections more efficient and accessible

Nowadays, drone inspections have become a common practice in almost every industry. Whether it’s for scheduling maintenance procedures across a power line or assessing property damage on a rooftop, drone inspections help inspectors collect essential data while minimizing potential hazards in the workplace.

Typically, a drone inspection consists of three key elements, outlined in the illustration below:

In theory, this is a pretty straightforward workflow to comprehend but in reality it can be far more complex to put into practice. While there are several factors attributable to this complexity, some notable factors are, the choice of technology – for instance, determining which platform and or sensor to use – and secondly, the intricate nature of the technology itself which requires skilled, professional operators. For most organizations looking to adopt this technology at scale, the latter part of these factors bears significant cost implications.

Pilot Training – A Necessity for Successful Drone Integration

As with any other profession, the investment of on-boarding existing or new staff on entirely new systems and technologies can be time consuming. The commercial drone industry is no different. Exceptional flying skills, processing aerial images for 3D modeling, interpreting and analyzing visual and thermal data – these are just a few competencies required of a professional operator – especially one conducting large scale asset inspections.

We at DJI understand that mastery of these skills is no easy feat, and therefore a key pillar of the Matrice 300 RTK’s development is to make these skills as accessible as possible. With up to 55 minutes’ flight time, IP45 protection rating, 6 Directional Sensing & Positioning and more, the M300 RTK is DJI’s most formidable industrial platform yet. To match its capabilities, the Zenmuse H20 Series payload offers up to 23x hybrid optical zoom, a 20MP zoom camera, 12MP wide camera, laser rangefinder with 1200m max range, and a radiometric thermal camera. Combined, the M300 RTK and Zenmuse H20 Series form a tough and intelligent drone solution suitable for a range of applications and use cases.

For routine data collection missions such as power line, oil rig, and railway inspections, Smart Inspection is an incredibly powerful feature set that makes drone inspections easier by lowering the pilot’s operational threshold.

Practically speaking, this means that complex and challenging inspections, performed for the very first time, could be assigned to more experienced pilots, while newer pilots can then later use the Smart Inspection features to perform the same inspection – safely and easily.

Smart Inspection consists of the following sub-features.

Live Mission Recording: Waypoint GPS navigation teaches your drone where to fly, and at what height and speed. With Live Mission Recording, this is taken one step further. Users can record every little detail of a flight mission such as aircraft movement, gimbal orientation, photo shooting, and zoom level to create sample mission files for future automated inspections. This makes even the most complex inspection projects a breeze.

AI Spot Check: The very nature of traditional inspection methods makes them prone to human error. Interestingly, this holds true for most current drone inspection solutions in the market – here’s why.

When performing an inspection with a drone, any minor changes, be it unstable wind conditions, movement of the gimbal (especially at high zoom levels) etc., may lead to a significant variation in the camera view. As you might expect, these can affect the accuracy and consistency of the data captured, impacting the overall inspection.

With AI Spot Check, this problem is significantly minimized. Users can mark objects of interest after a demo flight, then (by means of onboard AI algorithms), the aircraft will replicate the position, angle and framing automatically for future missions.

Waypoints 2.0: Waypoints 2.0 is an improved mission planning system that lets users create up to 65,535 waypoints and set multiple actions for one or more payloads, including 3rd party payloads too. With Waypoints 2.0, flightpath planning is optimized to maximize flexibility and efficiency, especially for more demanding inspections.

To make it even easier for operators, the M300 RTK and Zenmuse H20 Series offer a set of quick-tap functions that enhance usability.

High-Res Grid Photo

When inspecting extensive assets like powerlines or railways, High-Res Grid Photo allows users to save time and get highly detailed imagery. Simply frame an area of interest in a wide camera view, and the zoom camera will automatically capture a set of 20MP images of the area. These images are stored together with an overview image that can be viewed in greater detail.

Seamless User Interface

With up to four sensors integrated into one payload, the Zenmuse H20T brings a tremendous amount of versatility for carrying out inspections. To enable users to make the most of these sensors, the DJI Pilot app features an integrated user interface that lets you quickly switch between wide, zoom, and thermal camera views, and preview the zoom FOV while in wide or thermal camera view – all with a single tap.

If that’s not enough, the M300 RTK utilizes a new flight display system inspired by civil aviation standards. With Primary Flight Display, M300 RTK pilots have streamlined access to real-time flight and navigation information.

Since the very start of DJI’s inception, the company’s core vision has been focused on how to make complex technology safe, reliable and accessible. The M300 RTK and Zenmuse H20 Series are no exception. These products take cue from DJI’s consumer technology, bringing together a seamless solution for industrial applications be it inspection, search and rescue, firefighting, and more.

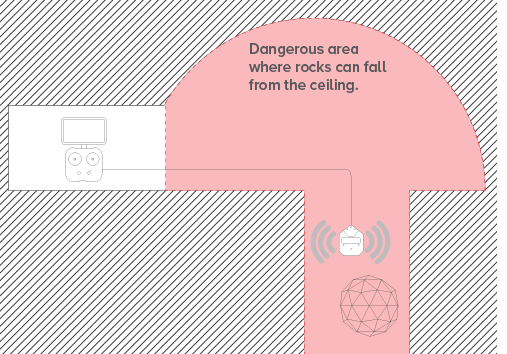

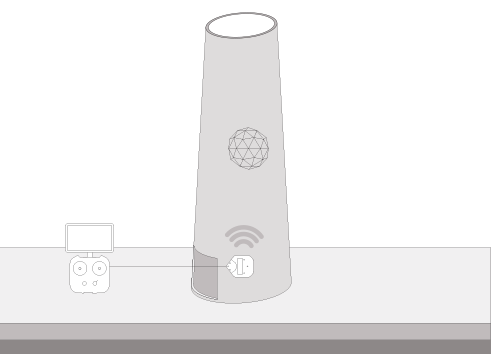

Flyability Range Extender (REx) Applications

Sewer Inspection

Because they are made of concrete, sewers tend to absorb the energy of radio control signal. If the pilot stands at the surface next to the shaft of the sewer, the propagation of the signal is very limited and so is the range of the drone. By deploying the Range Extender down the shaft of the sewer, the pilot can control the robot from the surface. This prevents the need for the pilot to expose himself to risks or uncomfortable situations.

Enclosed Spaces Inspection

The entry of workers into dangerous enclosed spaces is one of the key benefits of Elios but sometimes the material used to build the asset of interest perturbates signal propagation. By deploying the Range Extender inside the hazardous area, the pilot can operate Elios, from the outside in any situation, with peace of mind as the drone will always fly within reach of the signal.

Search and Rescue

In many cases, the immediate surroundings of a rescue scene can be dangerous for the rescuers. Keeping a certain distance from it is, very often, necessary. By deploying the Range Extender from the pilot base inside the research area, the Elios pilot will increase the quality of the signal between the ground control station and the drone and, consequently, increase the range of the drone.

Underground Mining

Many areas of underground mines are simply too hazardous for someone to venture in. As such, workers are requested to stay outside of these areas. By deploying the Range Extender inside these areas prior to a flight, an Elios pilot will gain some precious meters that make impossible missions, possible.

Braamd Inc. is the exclusive partner of Flyability in the Philippines. Please contact us to inquire.

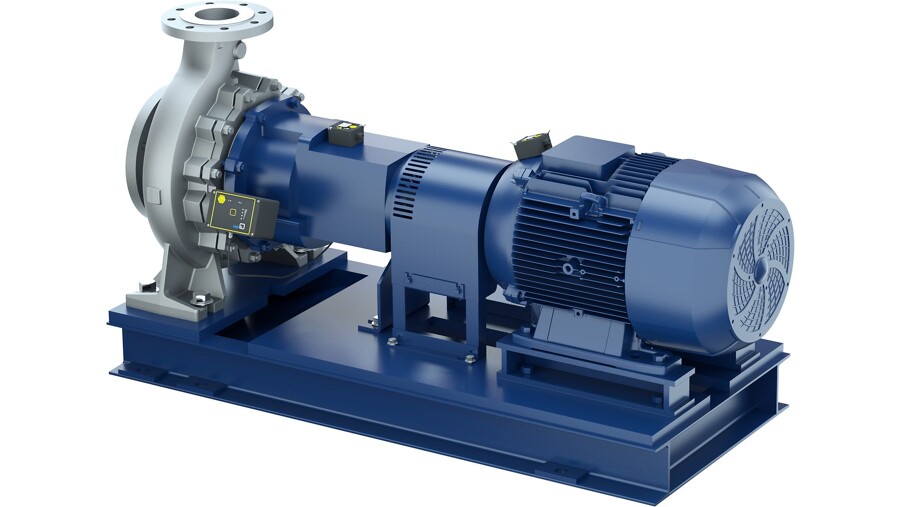

KSB SE & Co. KGaA adds 19 sizes to its MegaCPK type series. This means that users can now choose from 55 sizes with more than 78 hydraulic systems for these standardised chemical pumps. The available materials of grey cast iron, nodular cast iron and cast steel, stainless steel as well as duplex and special alloys, such as titanium and Hastelloy, result in a very wide range of applications. Fluids that require heating or cooling can also be transported.

The pumps are primarily characterised by their high output per size and their low energy consumption. Not only does this save electricity in operation, it also reduces the user’s initial investment costs. The developers placed particular emphasis on good suction behaviour with a low NPSH value in order to minimise the risk of cavitation, thus enabling smooth and stable pump operation even under difficult operating conditions. This ensures a high degree of reliability and improves the availability of an entire system.

By using the finite element method (FEM), a calculation method for the simulation of solids, the developers were able to achieve a high degree of strength and rigidity of the installed components while at the same time optimising the use of materials. After optimising all hydraulic contours by means of computational fluid dynamics (CFD), the improvements were verified in extensive test set-ups.

The new seal chamber design allows the installation of gland packings, all common mechanical seals compliant with EN 12756, as well as a large number of cartridge-type mechanical seals. Fully confined casing gaskets and minimised axial thrust ensure long service lives. To control and monitor operation, the pumps can be equipped with speed control, vibration and bearing temperature measurement and operating point monitoring.

In line with KSB’s common practice for industrial pumps, every pump is supplied to the customer with the impeller diameter trimmed exactly to the duty point. Impeller trimming combined with the large range of pump sizes available for selection helps ensure that the energy consumption of pumps is kept to the minimum necessary, even if they are run at fixed speed.

To learn more about KSB MEGA-CPK, please click below:

Electromagnetic flowmeters, often called magmeters, provide continuous flow indication of liquids via state-of-the-art electromagnetic technology based on Faraday’s Law. Because of this, magnetic flowmeters only work with fluids that are conductive. These flowmeters have no moving parts to wear or jam, offer low pressure drop, and generally require less maintenance than other types of flowmeters. They also have a wide sensing range and offer highly accurate readings.

DWYER SERIES IEF INSERTION ELECTROMAGNETIC FLOW TRANSMITTER

Paddlewheel flowmeters measure liquid flow rate with a rotating impeller, which is designed to provide a pulse when passing a magnetic or optical sensor. These units offer high accuracy and fast response time, while remaining cost-effective for a variety of applications. These mechanical-type flowmeters are ideal for applications where the media temperature varies or when the material being monitored is magnetic, such as in the oil and gas or utilities industries.

Dwyer Series PFT Paddlewheel Flow Sensor

Turbine flowmeters utilize a simple working principle based on a bladed rotor that rotates in correlation with the speed of the fluid passing through the meter. These meters are typically economical and easy to install. The simple but durable construction provides reliable performance for liquid and gas flow measurement. They prove to be most effective in applications with steady, high-speed flows.

Dwyer SERIES HFT IN-LINE FLOW TRANSMITTERS

Thermal dispersion flowmeters use a temperature element that is heated up beyond the media temperature, and the flow rate is determined from the rate at which the probe cools. There are no moving parts to wear or break, providing better long-term reliability than a paddlewheel or turbine flowmeter and the omni-directional sensing offers easy installation without concerns of flow alignment. In addition, the meter only needs to be inserted 10% into the flow, reducing the pressure drop. This technology is well-suited for applications where the pipe might be empty at times, as the active heating and cooling element helps it to remain unaffected.

Dwyer SERIES TDFS2 THERMAL DISPERSION FLOW SWITCH

Ultrasonic flowmeters measure flow by transmitting and receiving ultrasound waves within a pipe. No moving parts are needed, meaning there’s no pressure drop across the flowmeter and minimal maintenance is required, which allows these to be used in applications with sediment or other floating solids in the liquid. Optional clamp-on flowmeters offer even greater ease-of-use by eliminating the need to cut a pipe, preventing risk of leakage, and ensuring that the meter will not come in contact with the fluid being measured, which is ideal for applications where potable water is being monitored.

Dwyer SERIES UFM2 COMPACT ULTRASONIC FLOWMETERS

Variable area flowmeters, or rotameters, are some of the most commonly used flowmeters in the industry. They feature a simple construction that requires no power, providing cost-effective and reliable flow measurement. Their ability to be used with liquids and gases and no upstream/downstream straight piping requirements gives them the flexibility to be used in a variety of flow applications, including laboratories, medical equipment, and industrial applications.

Dwyer SERIES RM RATE-MASTER® POLYCARBONATE FLOWMETER

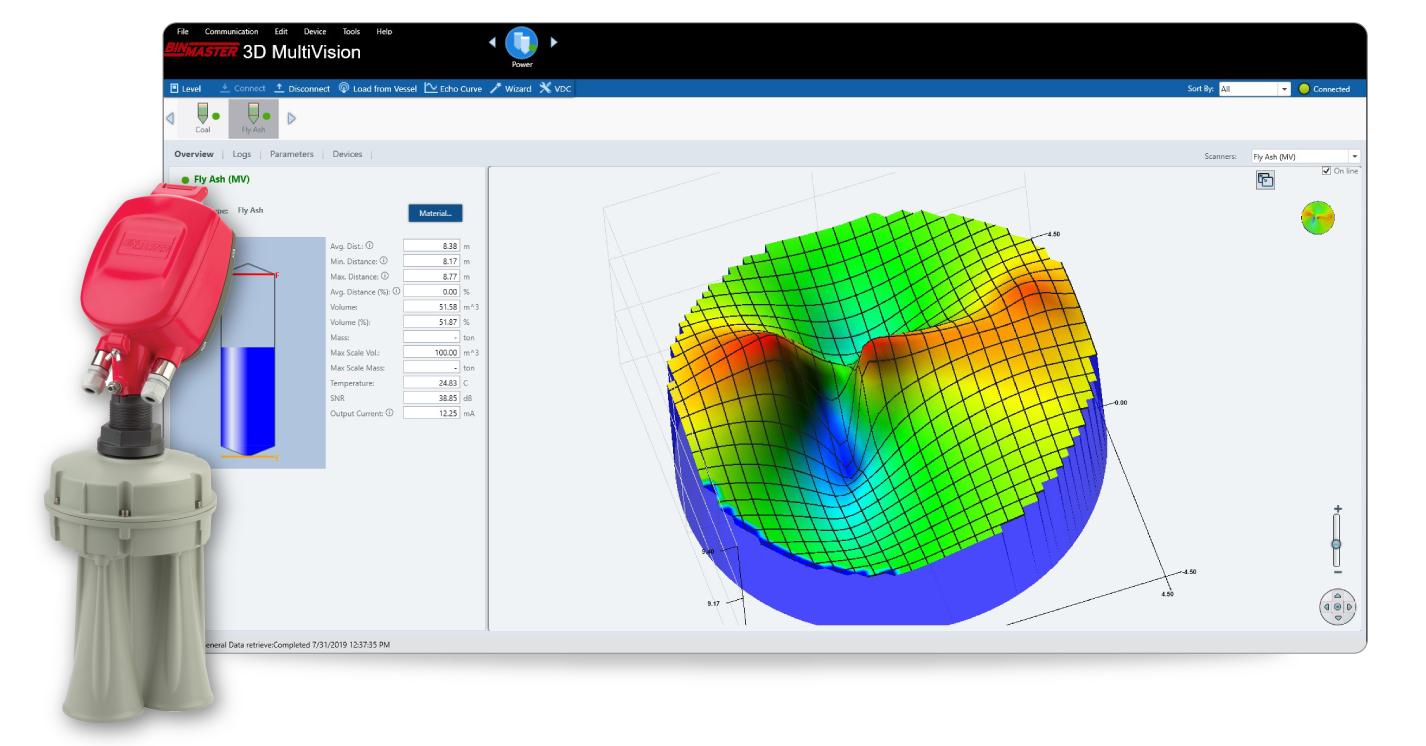

What makes the Binmaster 3D Scanner unique?