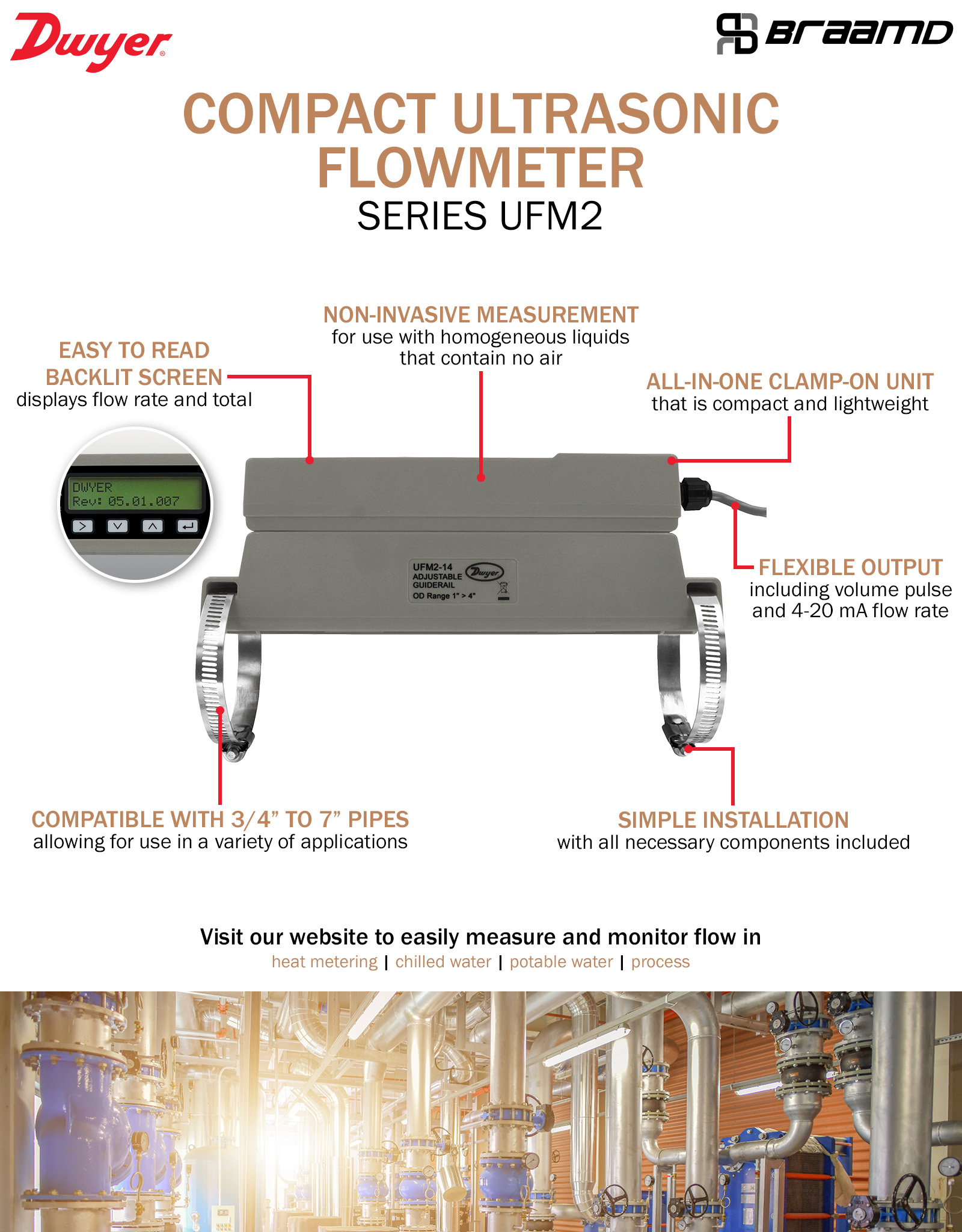

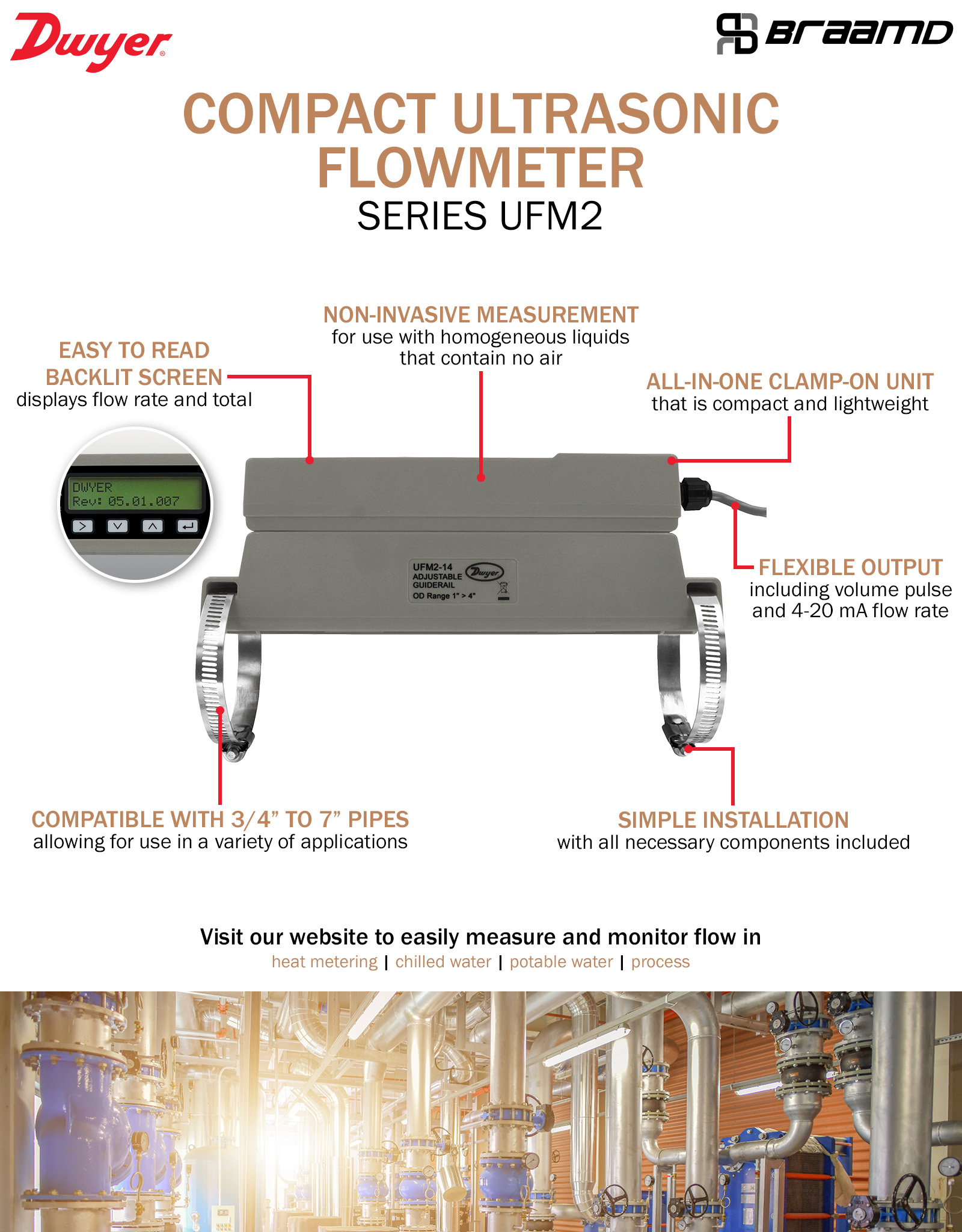

Dwyer Series UFM2 Compact Ultrasonic Flowmeter

Dwyer Series UFM2 Compact Ultrasonic Flowmeters are economical, clamp-on, ultrasonic flowmeters. It implements the transit-time difference to measure flow rates in 3/4″ to 7″ pipes. Applications include flow measuerment for heat metering and metering/monitoring of chilled water, potable water, and process applications.

Features:

Save on installation costs with non-invasive pipe measurement

Simplified installation with all necessary components included, such as converter, sensor, cables and mounting accessories

Fit application requirements with compact and lightweight design, that can be easily installed, all in one clamp-on unit intended for homogeneous liquids that contain no air

Cut down evaluation time with easy-to-read text displaying both flow rate and total with a convenient backlight for visual comfort

Please contact us to know more abut the Series UFM2 benefits and features.

[email protected]