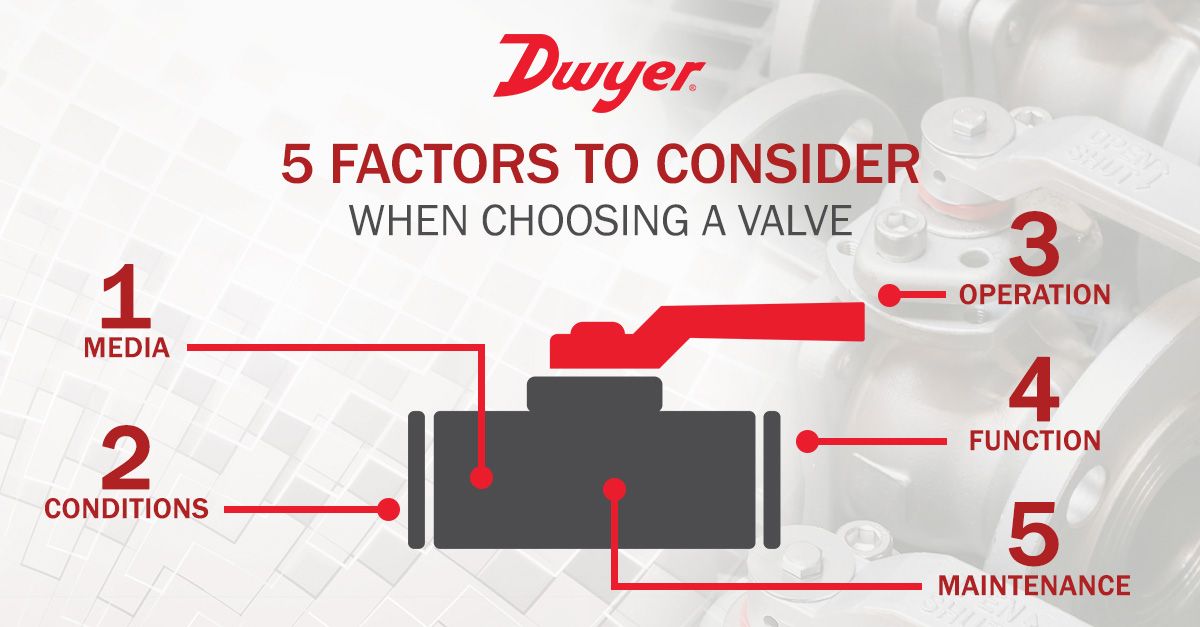

Dwyer Instruments: 5 Factors to Consider When Choosing a Valve

Valves are used to handle a wide variety of functions in controlling the flow of liquids and gases. With so many options available, it’s important to look at all of the factors to ensure you are selecting the correct valve for your application.

- Media Type

The characteristics of the liquid or gas type being controlled will determine the valve material that should be used. When monitoring harsh or corrosive materials, polytetrafluoroethylene (PTFE) and perfluoroalkoxy alkanes (PFA) are great choices, as they are able to withstand these conditions. When monitoring pressurized gases, it’s important to use metal valves for the highest level of safety.

- Application Conditions

The selection of the correct valve sizing is the most important step in selecting the right valve for your application. An improperly sized valve can cause operation issues within the valve or elsewhere in the system. In addition to this, determine the temperature, pressure, and flow rate that your valve will be operating under. In most cases, metal valves can withstand higher temperatures and pressures than plastic ones.

- Valve Function

Determine the need that your valve needs to fill. 2-way valves perform well for on/off control in a system, while 3-way valves can be used for on/off control, as well as for diverting or mixing media. Also, take note of whether your valve will be open or closed the most often. In order to extend the life expectancy, order a valve that is normally in that orientation and changes to the other direction when energized.

- Actuation Method

Another consideration to be made is how the valve is to be operated. Identify if the valve will be manually hand-operated or if the valve will need to be actuated to turn off and on automatically. If the latter is chosen, decide whether the unit is going to be used with an electric, pneumatic, or hydraulic actuator.

- Maintenance Requirements

If maintenance needs to be done regularly, ball valves are a great option as they resist clogging and are one of the simplest valve types to service. Ball valves are also available in 3-piece configurations, which consist of two end caps and a body. This allows the main body section to be easily removed for cleaning without disconnecting the end caps from the pipe, preventing the line from being shut down during maintenance.

W.E. Anderson™ Valve Product Lines

The W.E. Anderson™ division of Dwyer Instruments produces a broad line of competitively priced valves and valve control products, including: globe, butterfly, ball, manifold, actuators, and solenoid valves. Each valve type has a variety of options to meet specific application needs. Valve position indicators, valve positioners, and electric or manual pneumatic actuators are also available for a complete valve package. To learn more about Dwyer’s valve product line, please contact our Dwyer Sales & Application Engineers, sales@braamd.com.