Wind turbine blade inspection with Elios 3 Drone

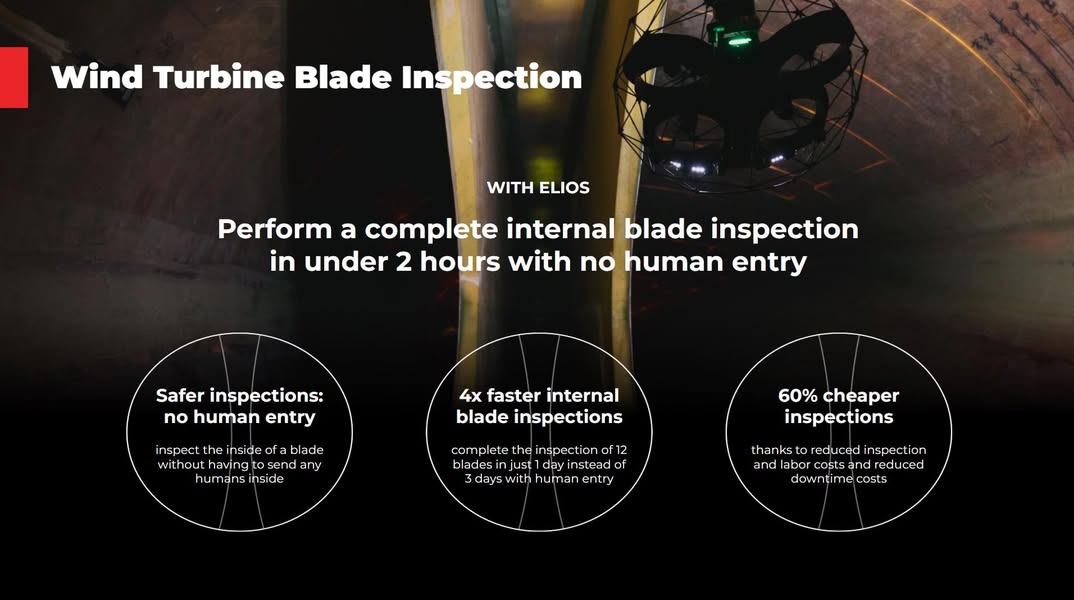

Perform a complete internal blade inspection in under 2 hours with no human entry.

90% of structural blade defects can only be detected from the inside. Missed defects can damage the motor and cost up to $ 1M to repair.

Internal blade inspections are a fundamental part of wind turbine maintenance operations. Unreported cracks, blisters, or fiberglass buildup can lead to reductions in energy production and serious issues with the blade and the motor.

By deploying the Elios 3 drone, it is possible to get uptower and complete an inspection of all 3 blades within 2 hours. All you need are two people and the Elios drone. Inspect two blades at a time and push the drone 30% further than a human would be able to go, create digital twins, use the LiDAR to measure cracks, and have the turbine back in operation in no time.

1. Safe inspections : no human entry

Inspect the inside of a blade without having to send any human inside

2. 4x faster internal blade inspections

Complete the inspection of 12 blades in just 1 day instead of 3 days with human entry

3. 60% cheaper inspections

Thanks to reduced inspection and labor costs and reduced downtime costs

Contact our drones team for a Wind Turbine Blade Inspection demo.

Email: sales@braamd.com, support@braamd.com