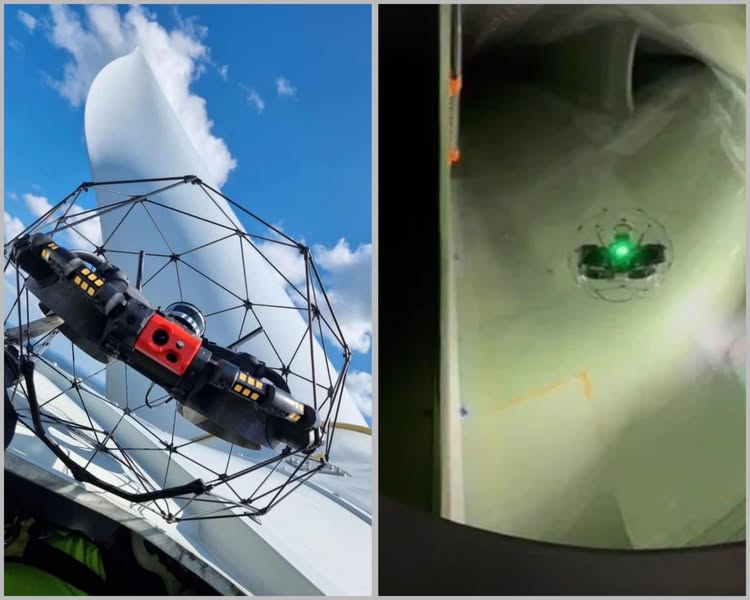

Elios 3 for Wind Turbine Inspection

Purpose of Inspections:

• Ensure safety and optimal performance.

• Identify structural damage or defects.

• Support preventive maintenance to avoid costly downtime.

Key Inspection Focus Areas:

• Structural integrity of the tower and mechanical components.

• Blades for cracks, deformation, splits, holes, or other signs of damage.

• End-of-year warranty inspections are crucial to identify defects before warranties expire, enabling customers to claim repairs from manufacturers.

Frequency:

• Inspections are typically performed every 1-5 depending on customer or based on warranty periods.

Data Shared with Customers:

• Primarily images pinpointing the exact location of defects.

• Periodically, videos for additional context.

• LiDAR data to create a replicated version of the blade and highlight damaged areas.

Benefits of using the Elios 3:

• Reduced Costs – Eliminates scaffolding and confined space entry, cutting labor and equipment expenses.

• Reduced Confined Space Exposure – Minimizes the need for personnel to enter hazardous space.

• Reduced Confined Space Exposure – Minimizes the need for personnel to enter hazardous spaces.

• 30% More Coverage Than Manual Inspections – Provides greater visibility into internal components that humans can’t reach.

• Faster Inspections – What takes days manually is completed in hours with Elios 3.

• Superior Data Quality – High-resolution imaging and LiDAR scans provide more accurate and repeatable results.

We invite you to witness Elios 3 Drone for wind turbine blade inspection, please contact us to book a free demo.