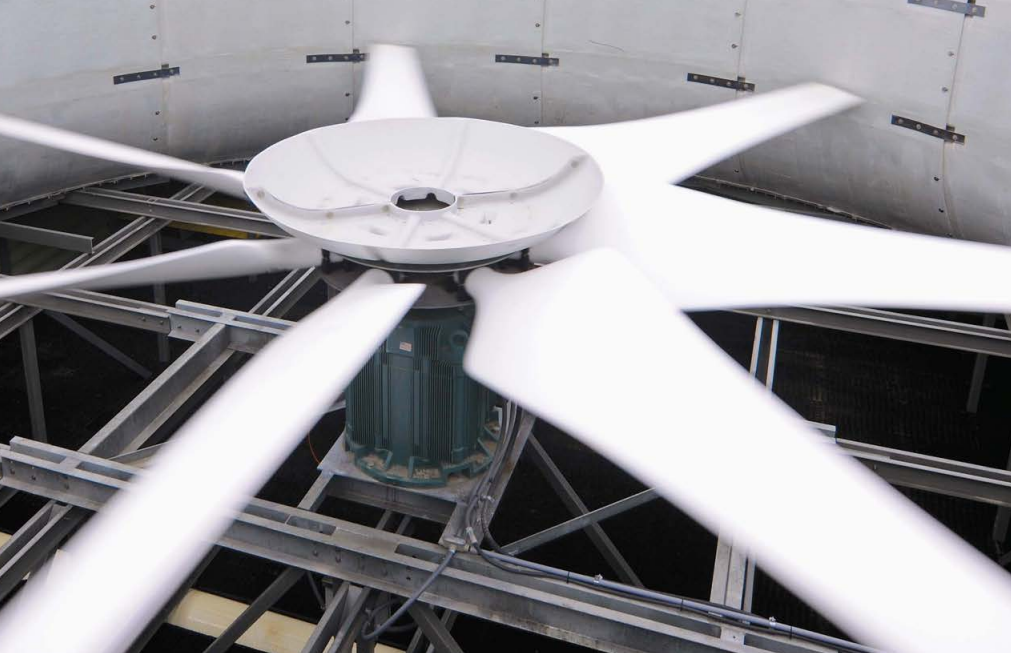

ABB Baldor-Reliance Direct Drive Cooling Tower DDCT Motor. New direct drive technology. Improves reliability, reduces maintenance, runs quieter and saves energy.

By combining the technologies of the field proven and power dense AC laminated frame RPM AC motor ith high performance permanent magnet (PM) salient pole rotor designs and the matched performance of an adjustable speed drive, ABB can offer high torque direct drive motors for cooling tower applications. The direct drive solution offers the benefits of variable speed control and eliminates the cost and maintenance required for traditional gearboxes or belted solutions. The fan couples directly to the motor and is controlled by a unique AC drive to provide optimal speed and cooling tower performance that runs quieter with reduced energy consumption. The drive is designed to accommodate the most common industrial communication protocols.

- Designed for outdoor duty to handle the extremes of 100% humidity and chemical environments

- Prevents water ingress along the shaft

- Motors are available with either foot or flange mount designs

- Shaft height, diameter and flange mounting dimensions can be directly interchangeable with some existing cooling tower gearbox designs

- High performance paint system and synthetic grease

- Long bearing lifetime exceeding L-10 100,000 hours

- For new or retrofit industrial cooling systems up to 650 rpm / 11,000 Nm

Motor features

- Vibration pad standard for FL58XX frame motors and optional on smaller motors

- Thermostats are standard on all motors. Their connection is required to validate the motor’s warranty.

- Winding stator RTDs are standard on FL58XX frame motors and optional for smaller motors

- Water ingress along the shaft is prevented with the slinger over Inpro seal for FL44XX and FL58XX and with V-ring slinger on smaller motors

- Multiple bolt circles on the N-end shield for easy replacement installations