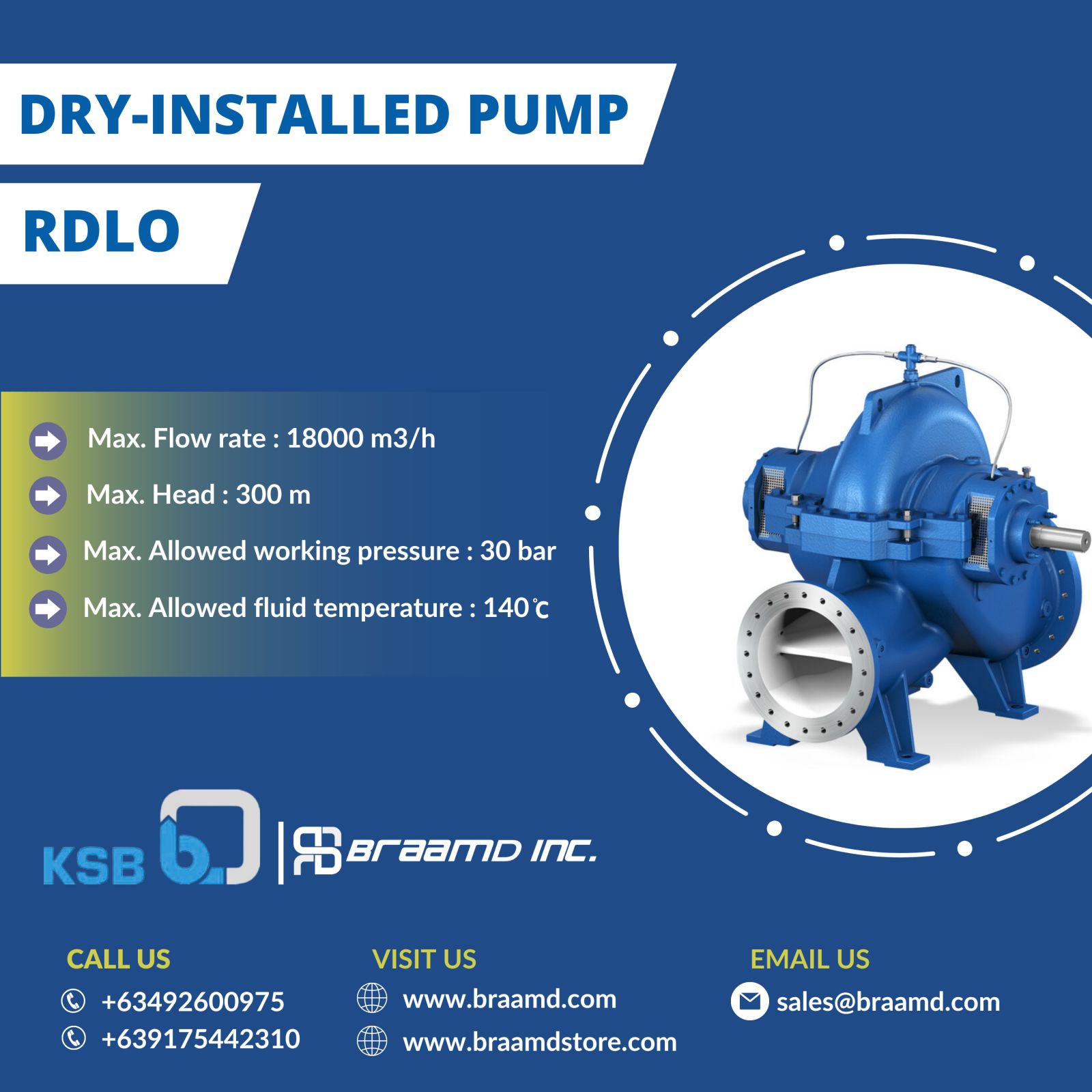

RDLO Axially split volute casing pump – KSB Pumps

High operating reliability

Since the casing is equipped with a double volute (compensating the radial forces) and a double-entry impeller (compensating the axial forces) the bearings only experience a minimum load. The theoretical operating life L10 for all sizes is at least 100,000 hours.

Low maintenance costs

The combination of solid bearing brackets, which are bolted to the upper casing part, the rigid shaft and the casing with double volute, guarantees low vibrations and long operating lives of bearings, seals and coupling. Corrosion and abrasion resistant materials ensure top service lives for shaft protecting sleeves, impeller and casing wear rings, and impeller.

Service-friendly design

The self-centering upper part of the casing and the spring-loaded rotor enable cover and rotor assembly without any further adjustments. For maintenance, the cover’s hexagon head bolts are completely removed from the casing. The casing split flange can therefore be easily and

thoroughly cleaned, and the inside of the pump is freely accessible.

Optimal tightness

The solid casing split flange of at least 80 mm at the upper and lower casing part ensures reliable and trouble-free sealing of the upper and lower casing halves.

Please click below to request for quotation: